MAINTENANCE & RELIABILITY

Adopting a Comprehensive Approach to Develop and Execute Superior Asset Management for Defense Equipment

Effective processes are only as effective as the equipment that facilitates them. Our Asset Performance Excellence Consultancy offers an integrated improvement initiative designed to enhance the management of physical assets in support of an organization's performance objectives. Many facilities often make the error of narrowly focusing on improving equipment downtime solely through maintenance efforts. However, root cause analysis studies reveal that true value creation remains suboptimal when addressing isolated areas. Our consultancy, on the other hand, devises and implements top-tier asset management programs through a holistic approach, encompassing elements such as reliability, asset sustainability, and work management optimization.

Performance Excellence begins by comprehending a company's culture and principles, encapsulated within five essential pillars as outlined below. These pillars serve as the cornerstone of a pyramid, identifying crucial enhancements required to support high-quality operations.

- Management Commitment

- Guiding Principles

- Goals and Objectives

- Leadership

- Organizational Structure

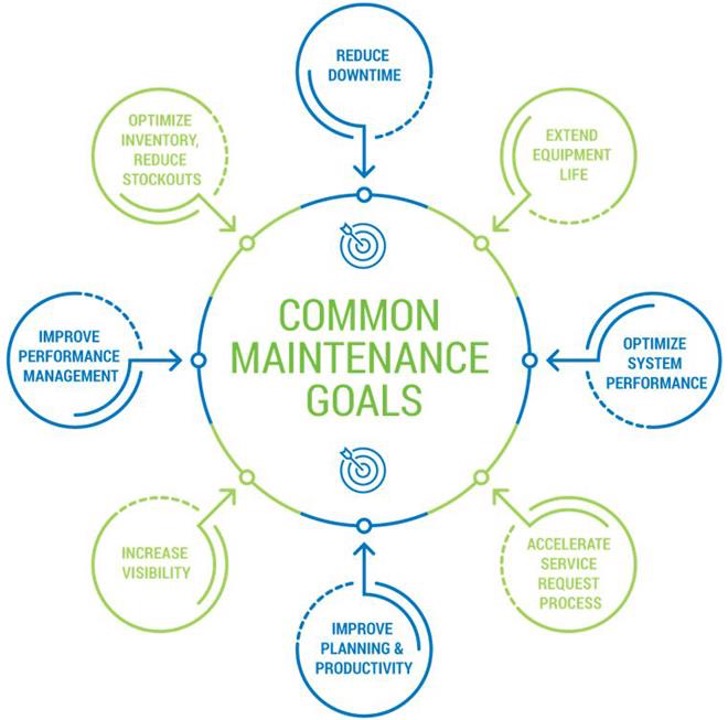

Our asset enhancement program is strategically crafted to yield tangible benefits for our clients, including increased asset availability, reduced maintenance expenses, optimized resource allocation, extended asset life, and diminished capital expenditures (CAPEX).

Moreover, for companies with a precise awareness of their challenges and a preference for a more targeted approach, we collaborate to analyze and address specific workstreams. Among the initiatives we undertake with our clients are:

- Maintenance Work Management, with a strong emphasis on planning and scheduling

- Reliability Engineering, encompassing asset sustainability processes

- Material Management and Procurement, specifically MRO (Maintenance, Repair, and Operations)

- Operations-Driven Reliability, covering aspects like operator standards, operator care, and operator maintenance

- Engineering, which may involve Life-Cycle Cost Analysis, RAM Studies, and similar endeavors

- High-Performance Management, incorporating measures, KPIs (Key Performance Indicators), dashboards, effective meeting strategies, and execution tactics.